Introduction

Any engineering problem

can be solved with one of the following approaches: analytical, experimental

and numerical; from these, numerical analysis is the single most effective tool

that can give insight to virtually any level of detail. Numerical analysis is

practically a science placed at the intersection of mathematics, computer

science and physics.

The most extraordinary

aspect of this science is that it takes shape in computer programs that model

the real life and can predict the behavior of matter. I won’t go into details

of how this modeling is done or how accurate it is. But it is notable that

numerical analysis is becoming more and more used in industry and this trend is

sustained by the development of IT.

The first FEA and CFD

analyses were performed in ’50 on 1 processor computers that had the size of a

large storage cabinet; today one can fit up to 32 processors and 512GB of RAM

into a normal size computer; this sure sounds impressive, but interesting

things are yet to come.

With the development of

hardware, the software also evolved extensively; we can say now that the FEA

software has matured in the aspect of accuracy, application and ease of use;

the CFD software has also reached a high level of detail insight taking

advantage of the visualization developments.

Now all this effort

comes at a price, sometimes very high; those that invested in research and

development of these wonderful tools must be compensated for their work. The

research goes in understanding the physics, creating better numerical schemes

and creating better algorithms and interfaces.

Fact is, in the last 20

years or so little was done in the first two directions. The physics and

numerical schemes are now available at almost no cost; the biggest endeavors

were made in computer science: making the code faster, the interface more

intuitive, automating more and more actions. This clearly reduces the time

spend and permits average engineer to make a simulation for fast results. But

the way I see it, this makes room for problems as well: lack of experience

personnel, limitations on problem setup and hidden errors in software.

Commercial

vs Open-source

Given that all the

information needed to create numerical solution is available, many software

solutions appeared; some of them are commercial and others are open-source; commercial

means you have to pay for the use of the software; but there are other payments

requested for the use of multiple processors, for customer support and

training; you cannot use the full computing power until you pay for a license

for parallel computing; basically you have pay for everything, and even to use

what is yours already.

Open-source on the other

hand do not charge for license and let you use all your computing power at no

costs; on the other hand they give support and training on demand based on a

fee; the fees are comparable with those for the commercial software. Therefore

open-source doesn’t mean free as in cost-free, but it can be seen more as the

freedom to access the knowledge and resources. The open-source software allows

user to access and improve the source code in order to make custom

applications.

The open-source

community is very active and it is interested in many fields, including engineering;

just to see some of the available open-source solutions, I have made a list

below:

SOFTWARE

|

USED FOR

|

QCAD

|

2D

& 3D CAD

|

FreeCAD

|

2D

& 3D CAD

|

SagCad

|

2D

& 3D CAD

|

Salome

|

3D CAD

Meshing

Post

Processing

|

GMSH

|

Geometry

Modelling

Meshing

Post

Processing

|

enGrid

|

CFD

Oriented Mesher

|

Discretizer

|

Structured

mesh generator for OpenFOAM

|

Code

Aster

|

Multiphysics

FEA

|

Elmer

|

Multiphysics

FE package

|

Impact

|

Explicit

FE Dynamics

|

Calculix

|

Pre-post

& FE solver, Abaqus-like syntax

|

MBDyn

|

Multibody

Dynamics

|

Dynela

|

Non-linear

Explicit Dynamics

|

Fenics

|

General

purpose FE solver for multiphysics applications

|

OpenFOAM

|

Multipurpose

CFD Solvers

|

Code

Saturne

|

3D

CFD solver

|

Gerris

|

2D /

3D CFD Solvers

|

Paraview

|

General

Purpose 3D Visualization

|

Python

|

Programming

language used for scientific computing

|

R

|

Mathematical

modelling & statistics (similar to S-Plus)

|

Scilab

|

Matlab/Simulink-like

mathematical programming environment

|

Octave

|

MATLAB

compatible mathematical programming

|

wxMaxima

|

Maple

like symbolic computing environment

|

Each code has its ups

and downs and here is not the place to go into detail and describe how good is

each of them and if it could give the same efficiency as the commercial

alternative.

A

case study on CFD tools

From the beginning I

want to be noted that I do not favor any CAE provider, commercial of open. But

I think that for the sake of good business, an objective comparison for the ups

and downs is appropriate. Therefore, I will compare two alternatives in the

field I am more comfortable with.

Let’s take the case of CFD;

based on the cfd-online.com software user forums, we have the following usage

of solvers (no. of CFD solvers threads on cfd-online forums @ 22.05.2015):

SOFTWARE

|

THREADS

|

% of USERS

|

FLUENT

|

41

845

|

42%

|

OPENFOAM

|

29

104

|

29%

|

CFX

|

16

468

|

17%

|

CD-adapco

|

7

595

|

8%

|

OTHER

|

4

305

|

4%

|

These data show that the

second most used CFD code is OpenFOAM, an open-source code; of course, these

figures are subject to discussion. I already mentioned the costs implied; from

my opinion, if costs are the most important, OpenFOAM is way cheaper than

Fluent.

Another big issue is the

accuracy these tools may provide; on the other hand I am obliged to ask what

the accuracy of a commercial code is and who grants that? In order to answer

this and not favor any party, I will show you the results of Aku Karvinen and

Hannu Ahlstedt documented in their paper. Aku and Hannu studied a separated

flow in a three-dimensional diffuser using OpenFOAM and Fluent; simulations

were performed using two turbulence models in both codes; the setup problem is

shown below:

|

| Geometry,

dimensions and coordinate systems of the three-dimensional diffuser |

A diffuser is a popular

separated flow test because of its apparently simple geometry. Many

experimental studies have been performed on diffusers and data is available for

comparison with numerical results. The working fluid is water that enters the domain

with a velocity of 1 m/s; based on the fluid properties and domain dimensions,

the Reynolds number is about 10000.

The objective is to see

how well are the velocity components computed with OpenFOAM and Fluent;

instances of the velocity distribution are determined at each 3 cm for the

first 15 cm of the diffuser. Below we can see a comparison between

experimental, Fluent and OpenFOAM results of the x component velocity; two

turbulence models have been taken into consideration.

In the following plots

one can see the mean streamwise velocities, x component at diffuser

cross-sections various distances from the origin using k-ε model; contour lines

are spaced 0.1 apart; the zero velocity contour line is thicker than others:

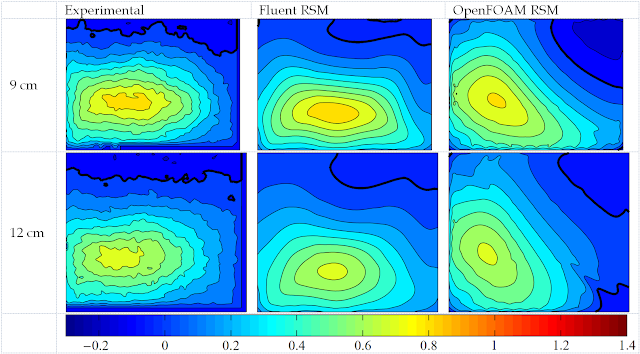

In the following plots

one can see the mean streamwise velocities, x component at diffuser

cross-sections various distances from the origin using Reynolds Stress model;

contour lines are spaced 0.1 apart; the zero velocity contour line is thicker

than others:

For even more results,

please refer to the original paper; the conclusion that we can get out of the

presented plots is that there are considerable differences between results

obtained using different turbulence models; the best results are obtained with

Reynolds stress model used in Fluent.

Unfortunately this model

is rarely used in industrial simulations because it is very time consuming and

turbulence models like k-ε and k-ω are faster. Comparing the plots from Fig.2, in

which the k-ε was used, one can see very similar results for both codes.

Therefore it can be concluded that for the applications used in industry,

Fluent and OpenFOAM can give remarkably similar results.

Conclusion

Keep in mind that the

success of one open-source solution doesn’t prove that all solutions are good

or immediately applicable; but, for the sake of business development I think we

can give them a chance to prove their capability.

In this article I showed

only a small fraction of what the open-source tools are capable of; in the next

issues of the magazine we will go into much greater detail on the opportunities

that open-source have to offer.

References:

Aku Karvinen and Hannu

Ahlstedt, Comparison of turbulence models

in case of three-dimensional diffuser, available online, at link